3D Jewelry Services

At Neo Group, we understand the transformative power of technology in the jewelry industry, which is why we offer a comprehensive suite of 3D services designed to revolutionize the design and manufacturing process. From CAD design to 3D printing and scanning, our cutting-edge services empower clients to unleash their creativity and bring their most ambitious jewelry concepts to life.

With a commitment to innovation, precision, and quality, we leverage state-of-the-art technology and expertise to deliver exceptional results that exceed expectations. Whether you’re a seasoned designer seeking to push the boundaries of traditional craftsmanship or an emerging artist looking to make your mark, Neo Group is your trusted partner in turning imagination into reality.

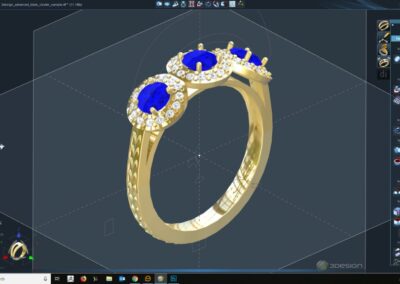

3D & CAD SERVICES

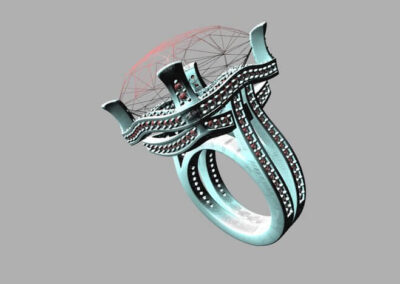

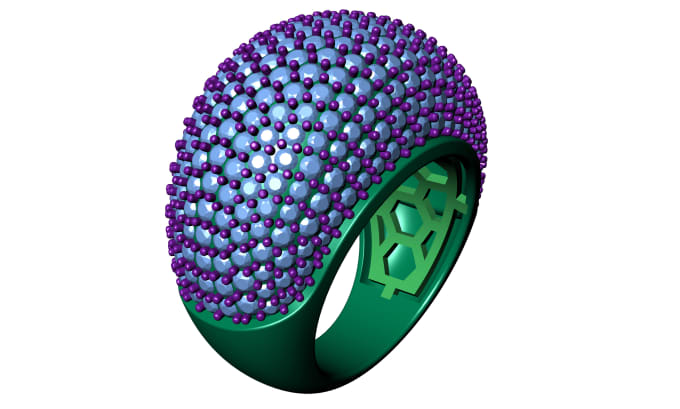

3D PRINTING & CAD

Neo Group’s 3D printing service stands at the forefront of innovation in jewelry manufacturing, offering unparalleled precision and versatility. Utilizing state-of-the-art 3D printers, we bring your digital designs to life with exceptional detail and accuracy. Whether you require intricate prototypes, custom components, or full-scale production runs, our advanced technology enables us to meet your unique specifications with ease. With a wide range of materials available, including wax for direct casting, resin for intricate detailing, and metals for functional prototypes, our 3D printing capabilities are adaptable to any project requirement. From concept to creation, Neo Group delivers excellence in every print, empowering you to bring your creative visions to reality with confidence and precision.

3D SCANNING

Neo Group’s 3D scanning service revolutionizes the jewelry-making process by seamlessly translating physical objects into digital designs with unparalleled accuracy. Using cutting-edge laser scanning technology, we capture even the most intricate details of your jewelry pieces, ensuring a precise and faithful representation in the digital realm. Whether you seek to replicate existing designs, create custom-fit pieces, or integrate traditional craftsmanship with modern technology, our 3D scanning service provides the foundation for limitless creativity. From heritage pieces to contemporary creations, Neo Group’s 3D scanning service offers a seamless bridge between the tangible and the digital, unlocking a world of possibilities for your jewelry designs.

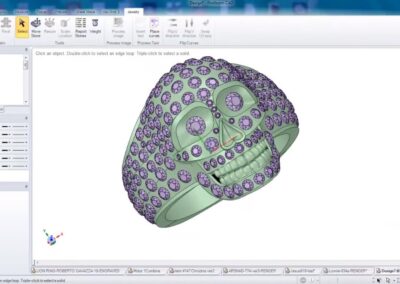

3D CAD DESIGN

Our CAD design services empower clients to explore limitless design possibilities. Whether you have a specific vision in mind or need assistance in conceptualizing your ideas, our skilled designers work closely with you to translate your concepts into detailed digital models. With expertise in software such as Freeform, Rhino, and ZBrush, we ensure that every design reflects your unique style and requirements.

Getting

Started

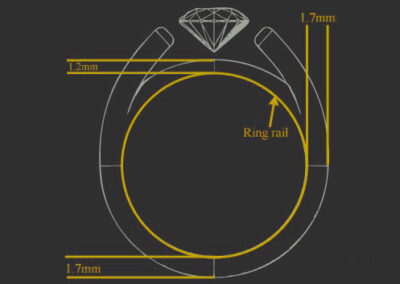

What is CAD design, and how can it benefit my jewelry design process?

CAD (Computer-Aided Design) is a digital technology that allows for the creation, modification, and optimization of jewelry designs in a virtual environment. With CAD design, you can visualize your ideas in three dimensions, make precise adjustments to shapes and proportions, and explore various design iterations quickly and efficiently. This streamlined process not only accelerates the design phase but also enables greater accuracy and flexibility, ultimately leading to the creation of more refined and innovative jewelry pieces.

How does 3D jewelry printing work, and what materials can be used?

3D jewelry printing, also known as additive manufacturing, involves building three-dimensional objects layer by layer from digital models. At Neo Group, we utilize state-of-the-art 3D printers capable of producing intricate jewelry designs with exceptional precision and detail. We offer a wide range of materials for 3D printing, including various metals such as gold, silver, platinum, and titanium, as well as resin materials for prototyping and casting.

What is 3D scanning, and how can it enhance my jewelry design process?

3D scanning is the process of capturing the physical geometry of an object and converting it into a digital model. This technology allows for the accurate replication of existing jewelry pieces or organic forms, providing designers with a foundation for further customization or reproduction. With 3D scanning, you can digitize intricate details, textures, and shapes, facilitating the creation of customized jewelry pieces that perfectly match your vision.

Can Neo Group assist with file preparation and optimization for 3D printing?

Yes, Neo Group offers comprehensive file preparation and optimization services to ensure that your designs are ready for 3D printing. Our experienced team can review and refine your CAD files, addressing any potential issues related to geometry, scale, or structural integrity. By optimizing your designs for 3D printing, we can maximize efficiency and quality, resulting in superior outcomes for your jewelry projects.

How long does the 3D printing process take, and what is the typical turnaround time?

The duration of the 3D printing process depends on various factors, including the complexity of the design, the chosen material, and the printer’s capabilities. At Neo Group, we strive to provide timely and efficient service, with turnaround times tailored to meet your specific project requirements. For detailed estimates and scheduling information, please contact our team for personalized assistance.

Neo Group

Crafting dreams into reality with precision and passion. Elevate your jewelry designs with our expertise and innovation

289 Soi Pramote 1/1 Surawong Road Suriyawong Bangrak, Bangkok 10500 Thailand